SPECIALISTS’ ONE-DAY SURGERY CENTER

Syracuse, NY

The project involved the relocation of an existing 6 operating room orthopedic surgery procedure center on the south side of the city to a new location with 8 operating rooms on the north side. The project involved the complete renovation of a 47,713 sf former office space into an outpatient surgery center. The building now affords convenient on-site patient parking with an entrance canopy for curb side patient drop off and pickup after surgery. The center at Taft Road is designed to provide larger operating rooms for more complex orthopedic procedures. It also provides Stage 1 and 2 Post Anesthesia Recovery and an Extended Recovery Suite which will provide 12 private patient rooms. The renovated facility is a single-story building constructed of Type II non-combustible construction, is fully appointed with sprinklers, equipped with a fire alarm and smoke detection system and divided into three smoke compartments in compliance with NFPA 101 Life Safety Code. The building is comprised of 8 operating rooms, (with future capacity for 10), a prep/hold area with 16 patient stations and a 27 patient station recovery area. The Central Sterile processing area includes separate rooms for gross decontamination of medical instruments, sterilization and clean instrument storage. Multiple nurse’s stations with satellite staff stations with hand washing facilities will be situated in the prep/holding and recovery areas to provide monitoring of traffic throughout the center. Additional spaces include soiled and clean linen rooms, locker rooms, offices, conference rooms, reception/waiting room for 67 people and multiple ADA accessible patient and staff toilet rooms. There will be a small 3,083 sf medical office tenant space that is separated from the Center by a one hour fire rated wall. It will have its own separate entry.

Quick Specs

| Owner | Specialists’ One-Day Surgery, LLC |

| Type of Work | Renovation |

| Project Cost | $10 Million |

| Project Size | 47,713 sq ft |

SCOPE OF MECHANICAL, ELECTRICAL AND PLUMBING WORK

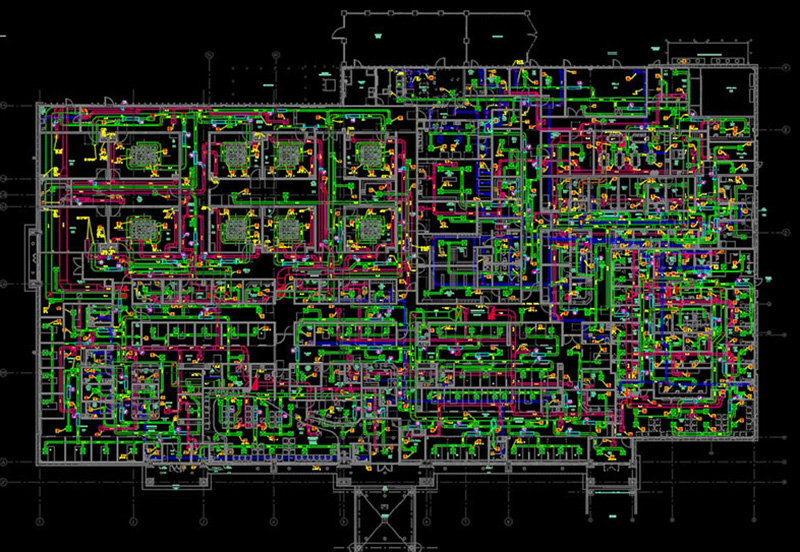

- Provision of three gas-fired rooftop units to serve all areas outside of the operating room and central sterile processing suites. This works in conjunction with multiple variable air volume boxes.

- Provision of three custom air-handling units to serve the eight (8) operating rooms, including two air-cooled chillers.

- OR system includes supply and return variable air volume boxes and a central steam generator for duct humidifiers.

- Ductless fan coil unit with remote condensing unit for computer IT closet.

- Multiple exhaust fans for toilet rooms, electrical and communications rooms, break room and multiple rooms in central sterile processing.

- DDC energy management system to provide temperature control.

- Three (3) 1500 MBH high efficiency boilers and associated boiler loop pumps. The third boiler provides N+1 redundancy.

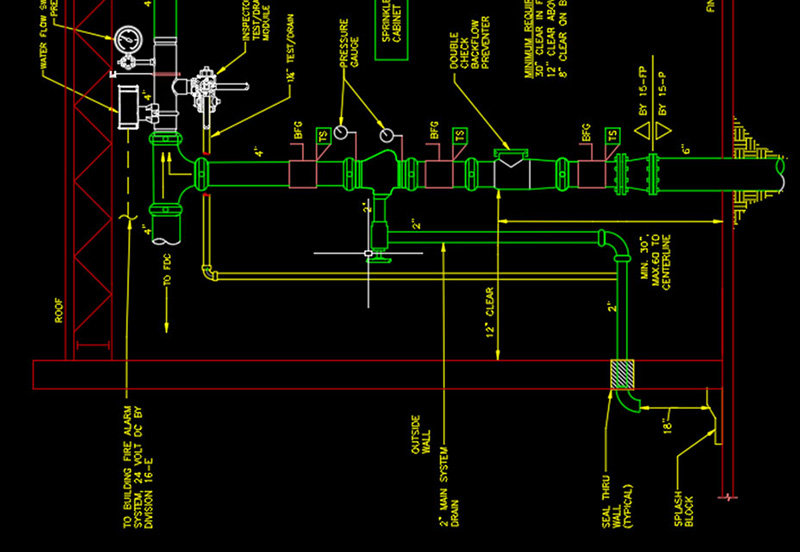

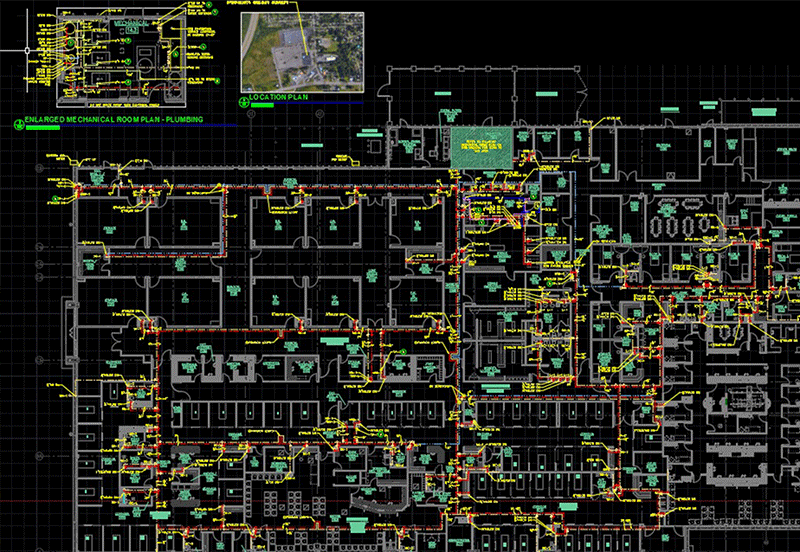

- Provided a separate domestic water and fire protection water services with RPZ backflow prevention and the service entrance in compliance with the Department of Health.

- Removed existing plumbing systems completely and provided sanitary and domestic water systems to serve plumbing fixtures and equipment in compliance with NYSECC and ADA regulations.

- Deleted one of two existing gas services to building and upgraded the existing in coordination with the Power Company to serve boilers, rooftop units and other gas-fueled equipment.

- Provided roof drains and emergency roof drains and a storm drainage system.

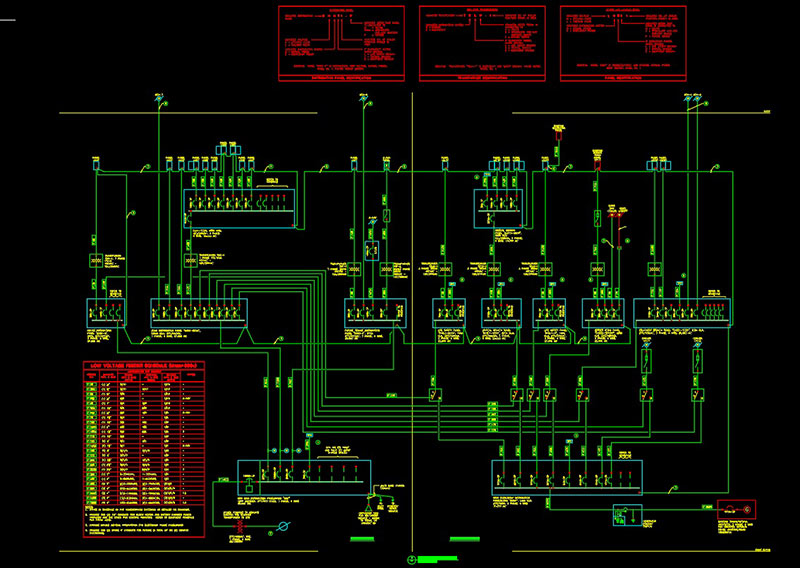

- Recondition an existing 500 kW outdoor diesel-driven emergency generator with integral fuel tank, provision of a generator docking station for testing and portable generator connection, and seven (7) automatic and manual transfer switches.

- Complete 800 ampere, 277/480 volt emergency power distribution system with separate branches for life safety, critical and equipment loads.

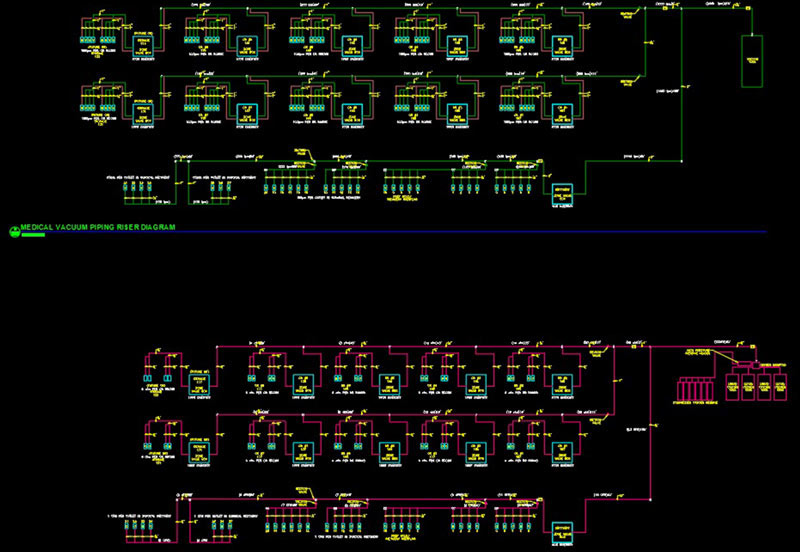

- Digital mixed function medical alarm panels at the nurse’s stations and new zone valve boxes.

- Removed the existing sprinkler system and provided a complete automatic wet pipe sprinkler system in compliance with NFPA 13 utilizing quick response sprinklers. An existing computer server room fire suppression system remains and will be monitored by the fire alarm system.

- Fire Department connection at the east side of the building per Fire Department requirements.

- High efficiency building mounted outdoor LED site and security lighting, with time clock and photoelectric controls.

- Provision of an intelligent, point addressable fire alarm and carbon monoxide detection system that is supervised and automatically reports to an approved central station.

- Audio/visual UL 1069 supervised nurse call system for prep/hold, recovery and extended recovery areas.

- Complete data and voice IT communications cabling system, completely terminated, tested and certified.

- Highly efficient interior lighting system, operating at less than 0.9 watts per square foot, utilizing light emitting diode (LED) lamp sources. Many portions of lighting system are controlled by occupancy sensors and digital controllers.

- Designed a new 10-tank oxygen and 10-tank nitrous-oxide medical gas manifolds to serve operating and recovery room wall outlets. Includes digital master alarm panel and area alarm panel(s).

- Central vacuum system to serve operating and recovery room wall outlets with duplex “oil-less” claw type oxygen vacuum pump.

- Upgraded the existing 800 ampere service to a new 1600 ampere, 277/480 volt, 3 phase, 4-wire upgrade with Power Company. Included removal and replacement of the Power Company’s existing pad-mounted transformer, riser pole and underground primary and secondary feeders.